SADM Quality Specification

SADM Quality Specification

SADM possesses characteristics which present significant challenges throughout the production and machining process. Process control is key to our success in the production of quality machined parts. Quality is closely monitored at each step throughout our manufacturing process to achieve the highest quality finished SADM and SATB parts.

The following pictures are provided to demonstrate acceptable quality levels at final inspection.

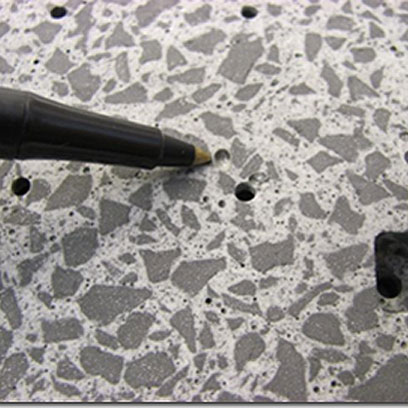

SURFACE:

- Voids: – A void is a pore that remains unfilled with polymer and fibers in a composite material. Void content in composites is represented as a ratio, also called void ratio, where the volume of voids, solid material, and bulk volume are taken into account.

Porosity is determined by dividing the volume of voids by the total volume of a material to determine a percentage. For example, Porosity (%) = (Volume of Voids / Total Volume) x 100.

For aerospace and marine applications, a void content of approximately 1% is still acceptable, while for less sensitive applications, the allowance limit is 3-5%.

We work closely with our client’s engineering staff to meet their particular application, and smaller voids specified by the client can be considered. The methods for measuring and reworking voids shall be specified and agreed to by both parties before a quote can issue.

Please specify any custom requirements when submitting your quote request.

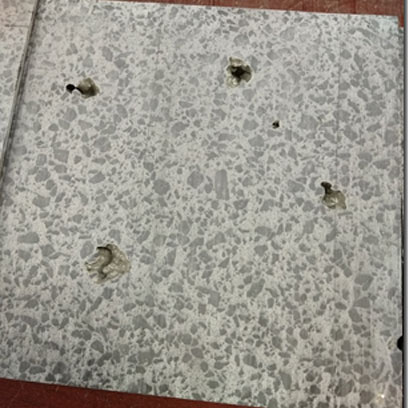

EDGE BLOWOUT:

Due to the nature of SADM, some amount of edge chipping should be expected. The level of acceptability is determined by the location and extent of the chipping on the finished part. This characteristic becomes more pronounced on thin walls.

Please specify any custom requirements when submitting your quote request.

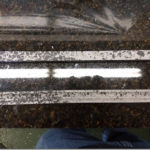

LEAD DISTRIBUTION:

Leaded rubber particles are distributed as uniformly as possible through our SADM mixing process, though the concentration in places may be random.

Please specify any custom requirements when submitting your quote request.