SADM Product Data Sheet

Material Performance Data

Acoustic Performance

Mechanical Performance

SADM MATERIAL DATA

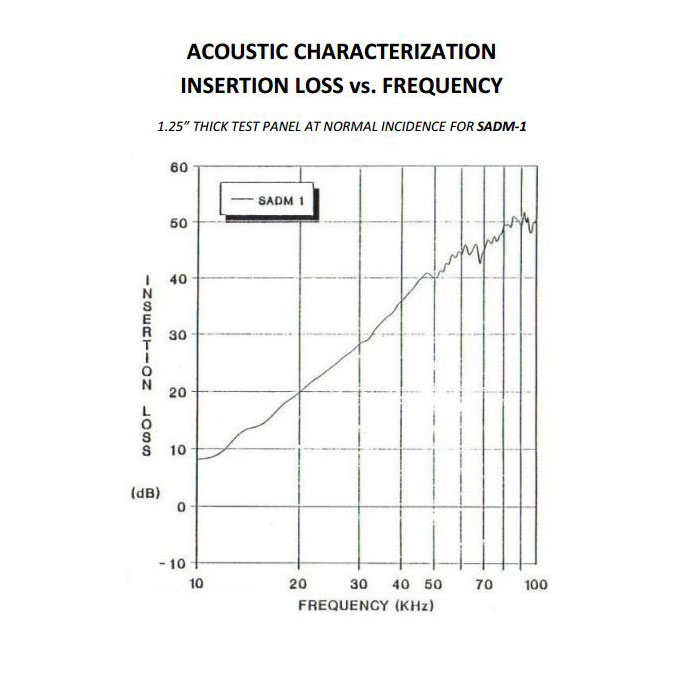

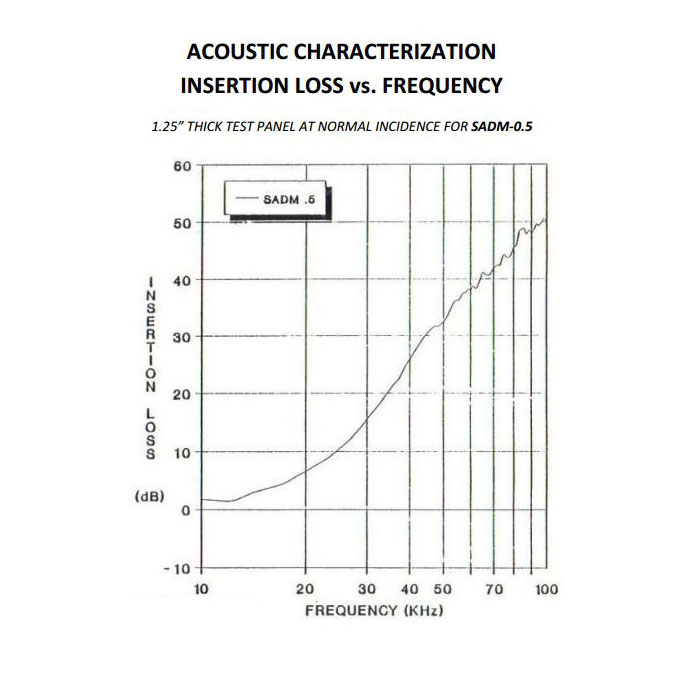

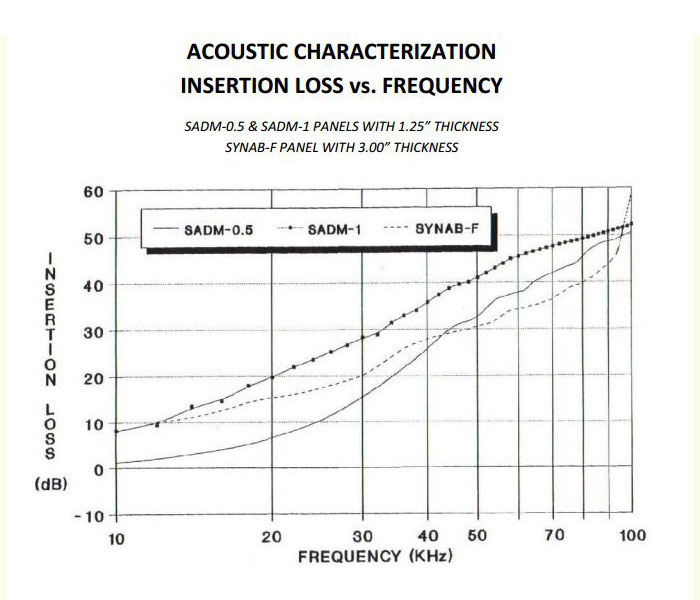

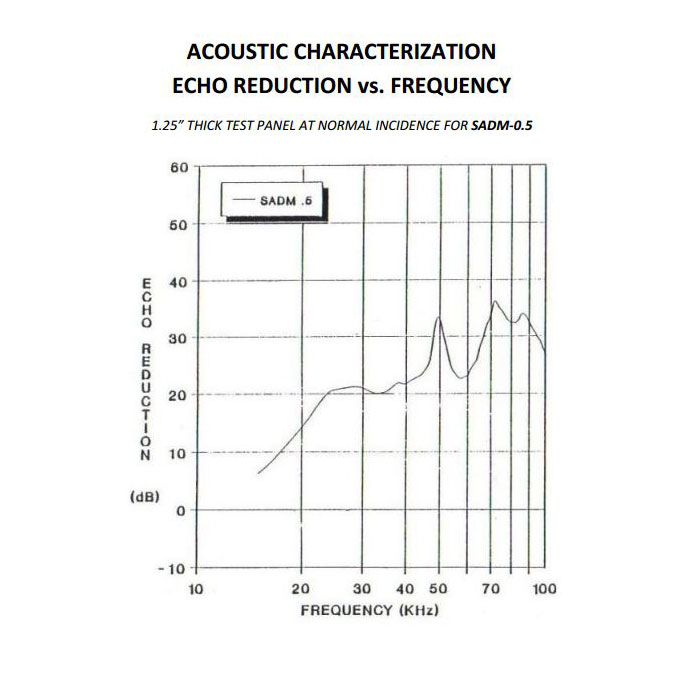

Acoustic Performance

INSERTION LOSS

| Frequency | Angle of Incidence | Insertion Loss |

| 60 Hz | 0 degrees | +42.1dB |

| 100Hz | 0 degrees | +54.5dB |

| 150Hz | 0 degrees | +64.1dB |

| 200Hz | 0 degrees | +76.7dB |

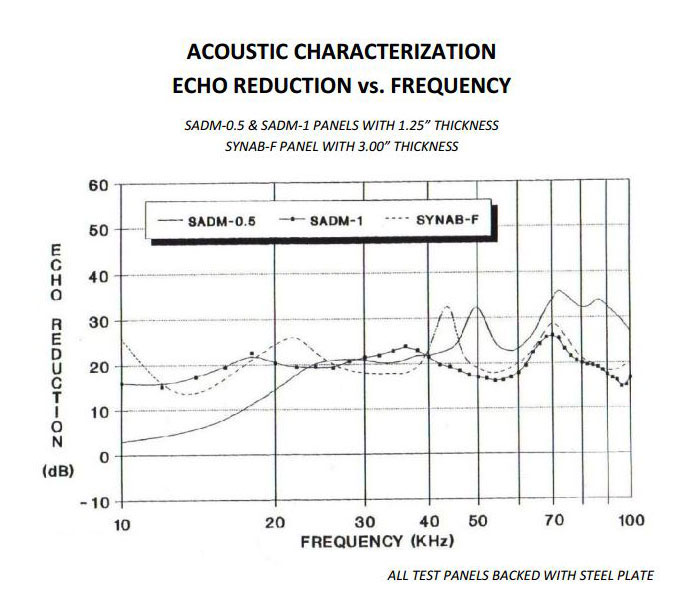

ECHO REDUCTION

| Frequency | Angle of Incidence | Echo Reduction |

| 60 kHz | 0 degrees | +19.9dB |

| 100 kHz | 0 degrees | +17.1dB |

| 100 kHz | 45 degrees | +11.7dB |

| 100 kHz | 60 degrees | +7.9dB |

| 100 kHz | 75 degrees | +9.5dB |

| 100 kHz | 80 degrees | +12.2dB |

| 150 kHz | 0 degrees | +20.5dB |

| 200 kHz | 0 degrees | +19.9dB |

| 200 kHz | 0 degrees | +23.9dB* |

| 200 kHz | 45 degrees | +14.4dB |

Mechanical Performance

Tensile Strength

| Sample No. |

Width(in) | Thickness(in) | Max. Load(lbf) | Tensile Stress @Max Load(psi) |

Elastic (Young’s) Modulus(psi) |

% Elongation @Max Load |

Break Area |

| 1 | 0.5165 | 0.2465 | 56.7 | 445 | 139,000 | 0.38 | In gauge area |

| 2 | 0.5145 | 0.2425 | 39.1 | 313 | 104,000 | 0.33 | In gauge area |

| 3 | 0.5170 | 0.2425 | 46.2 | 371 | 104,000 | 0.44 | Near grip |

| 4 | 0.5145 | 0.2480 | 56.9 | 446 | 132,000 | 0.36 | Near grip |

| 5 | 0.5150 | 0.2470 | 48.1 | 278 | 106,000 | 0.48 | In gauge area |

| Average | 49.4 | 371 | 117,000 | 0.40 | In gauge area |

Compressive Strength

| Sample No. |

Bulk Modulus (psi) |

Compressive Stress at Yield(psi) |

Max Load(lbf) | Deformation at Max Load(in) |

| 1 | 113,000 | 1,760 | 457 | 0.0305 |

| 2 | 87,500 | 1,350 | 325 | 0.0312 |

| 3 | 74,000 | 1,080 | 285 | 0.0277 |

| 4 | 114,000 | 1,840 | 455 | 0.0294 |

| 5 | 105,000 | 1,780 | 470 | 0.0422 |

Average

| 98,600 |

1,560 |

398 |

0.0322 |

|

Std. Dev.

| 17,275 |

332 |

87 |

0.0057 |

|

Density and Specific Gravity

| Sample No. |

Density D23°C g/cm^3 |

Specific Gravity 23/23°C |

| 1 | 1.8739 | 1.88 |

| 2 | 1.8225 | 1.83 |

| 3 | 1.9718 | 1.98 |

| Average | 1.8894 | 1.89 |

| Std Dev | 0.0759 | 0.08 |

Shear Strength

| Sample No. |

Punch Diameter (in) |

Thickness (in) | Shear Edge Area (in^2) |

Max Load (lb/f) |

Shear Modulus (psi) |

Shear Strength (psi) |

| 1 | 0.9985 | 0.2072 | 0.6499 | 894 | 210,200 | 1375 |

| 2 | 0.9985 | 0.2678 | 0.8400 | 1030 | 141,200 | 1226 |

| 3 | 0.9985 | 0.3290 | 1.0320 | 894 | 89,520 | 866 |

| 4 | 0.9985 | 0.2698 | 0.8463 | 1009 | 114,300 | 1192 |

| 5 | 0.9985 | 0.2417 | 0.7582 | 1080 | 102,100 | 1424 |

| Average | 0.8253 | 981 | 131,500 | 1217 |

Important notice to purchaser: All statements, technical information and recommendations herein are based on tests we believe to be reliable, but the accuracy or completeness thereof is not guaranteed, and the following is made in lieu of all warranties, expressed or implied, including the implied warranties of merchantability and fitness for purpose. Sellers and manufacturers only obligation shall be to replace such

quantity of the product proved to be defective. Before using, user shall determine the suitability of the product for its intended use, and user assumes all risk and liability whatsoever in connection therewith. Neither seller nor manufacturer shall be liable either in tort or in contract for any loss, damage, direct, incidental, or consequential, arising out of the use of, or the inability to use the product. No statement or recommendation not contained herein shall have any force or effect unless in an agreement signed by officers of seller and manufacturer

quantity of the product proved to be defective. Before using, user shall determine the suitability of the product for its intended use, and user assumes all risk and liability whatsoever in connection therewith. Neither seller nor manufacturer shall be liable either in tort or in contract for any loss, damage, direct, incidental, or consequential, arising out of the use of, or the inability to use the product. No statement or recommendation not contained herein shall have any force or effect unless in an agreement signed by officers of seller and manufacturer